What does PEC stand for?

PEC is an acronym for Pulsed Eddy Current.

What is BonPEC?

BonPEC is the cost effective solution for corrosion detection and monitoring of insulated components in the Oil & Gas and Energy sectors.

What type of inspection method belongs to BonPEC?

It belongs to the Eddy Current inspection method.

What is the basic working principle of BonPEC?

BonPEC is based on the Pulsed Eddy Current principle (PEC).

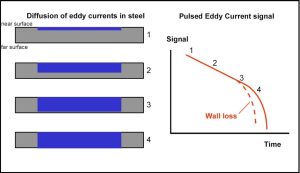

What is Pulsed Eddy Current?

Pulsed Eddy Current is Eddy Current induced by suddenly switching of a constant magnetic field, therefore Eddy Current generated in this “transient”.

What is BonPEC designed for?

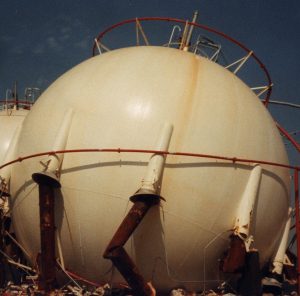

It is designed for detection and monitoring of Corrosion Under Insulation (CUI).

What are the primary applications of BonPEC ?

Insulated, fireproofed, coated, or encrusted vessels, columns, storage tanks, spheres, pipe, ship hulls, offshore platforms and wells.

What are the BONPEC primary limitations?

Applicable only on Carbon Steel and Low Alloyed Carbon Steel.

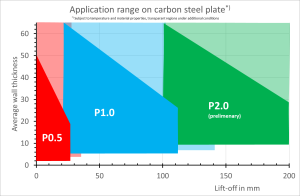

(Depending on the available probe) In presence of coating and/or stainless steel weather proofing cladding nominal wall thickness 2 – 70mm, stand-off/insulation 0 – 250mm, diameters 2” up to flat plates.

When the weather proofing cladding is Aluminium, then the minimal detectable Average Wall thickness is approx. 3 mm at 20ºC and it is function of the temperature.

When the weather proofing cladding is Ferromagnetic, then the general equipment performances and application range are halved (WT < ~35mm, LO < ~100mm).

Can you inspect non-ferrous materials with BonPEC?

No, at present BonPEC is restricted to ferritic material of Carbon Steel and Low Alloyed Carbon Steel. However, development of BonPEC for non-ferrous materials is nearing completion.

Can BonPEC inspect through fireproofing, or refractories and if so is there any limitations?

Yes and the limitations are the same as the primary limitations. A ferritic steel wire mesh will not affect a reading but reinforcement rods will do, therefore a minimum of 4” mesh size or pattern is required.

What are the temperature limitations of the base object material for a BonPEC inspection?

What types of insulation and cladding can BonPEC inspect through?

The insulation type need to be non-magnetic and non-electrical conductive. The weather proofing cladding/sheeting can be Aluminium, Stainless Steel or Galvanised ferrous material, for the latter sheeting type the general performances are halved.

Is there a dead zone for a BonPEC probe?

There is a “dead zone” which depends on the coil minimum time of each probe. The bigger the probe size, the stronger the received signal and the larger its coil minimum time.

What does the coil minimum time affect?

It affects the minimum detectable Average Wall Thickness (AWT).

How much coverage does BonPEC typically have on an elbow, pipe, etc?

This is corrosion mechanism dependent and the grid size may be adjusted for straight pipe to 100% coverage depending on the corrosion characteristics. Elbow’s intrados area is accessible by placing the PEC probe orthogonally to the flow.

Does ice have any effect on BonPEC– cryogenic service?

Ice does not have an effect, as it does not influence the generated magnetic field.

Does BonPEC need external power supply to be operated?

No the BonPEC equipment is powered by Battery Packs.

Is BonPEC intrinsically safe?

No this system is not explosion proof and may have the potential to cause a spark, if a connection or wire is broken.

Can BonPEC tell the difference between a mechanical disturbance and an artefact of corrosion?

Yes the technician has the ability to view the raw signal or data in real time and evaluate the influence of surrounding objects.

Can BONPEC differentiate between internal and external corrosion?

Under Laboratory condition with constant lift-off it is possible to determine whether an indication is internal or external by observing the registered signal amplitude.

In field operation, insulation does not have a constant thickness and therefore it will not be possible to discriminate whether an indication is internal or external.

Does the product inside a pipe affect the BonPEC data?

When non-magnetic and non-electrical conductive it will not affect the data.

Can BonPEC differentiate between internal and external corrosion?

Under Laboratory condition with constant lift-off it is possible to determine whether an indication is internal or external by observing the registered signal amplitude.

In field operation, insulation does not have a constant thickness and therefore it will not be possible to discriminate whether an indication is internal or external.

Is BonPEC sensitive to Stagnant Vs. Moving waters?

Water will not affect BonPEC results as long as it does not penetrate inside connectors and the probes coils. However, vibrations in the object under investigation, need to be prevented as much as possible as it reduces the applicable wall thickness and Liftoff range of BonPEC.

Is the BonPEC technology sensitive to internal and external coatings? Which ones?

The system would see an influence from any magnetic of ferrous coating and the application would be evaluated for prior history or if further testing would be required.

Is BonPEC sensitive to internal lining materials?

When non-magnetic and non-electrical conductive, BonPEC will not be sensitive to internal lining material such as: HDPE, FRP or Non-Ferrous Claddings.

Is a calibration block needed to set up the BonPEC equipment and to perform the inspection?

No calibration block is required to perform the inspection; calibration or reference measurement is performed on the component to be tested or on a sample having the same material parameters as the object to be inspected.

Can BonPEC detect pitting corrosion?

BonPEC is not designed for detection of localized pitting and holes. It is designed for generalized corrosion detection. When pitting is grouped and not localized, then it may give reliable indication.

Can BonPEC inspect welds, preferential weld corrosion?

BonPEC is not a weld inspection tool.

Does a BonPEC inspection need to be verified by other NDT methods to validate findings?

The principal validation method is UT. BonPEC is a relative inspection method which compares the reference data signal with all other measurements. As a result it gives an Average Wall Thickness variation in the object. During validation of the findings, the Reference location and the larger deviations should be checked over all footprint area. It should be noted that within the footprint, the local Wall thickness could be thinner than the given Average Wall Thickness.

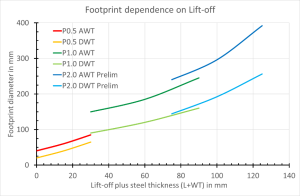

What is the BonPEC Footprint?

The footprint is the magnetized area on the inspected object. The induced Pulsed Eddy Current decay will give the Average Wall Thickness value compared to the Reference.

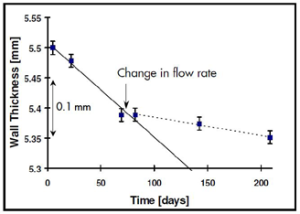

What is the BonPEC equipment accuracy?

The general BonPEC measurement accuracy is 5 % of the reference value and this will be valid when the local wall reduction will not exceed more than 50% of the reference WT and when the lift-off/insulation variations will be within 50% of the reference lift-off.

What is the BonPEC equipment repeatability?

The general equipment repeatability deviation is ±2%.

What is the BonPEC equipment detectability?

Detectability depends on the indication and footprint size. To be detected an indication must have a surface extension of more than a third of the footprint area and the volume deviation to the reference area must be more than 10%.

Can BonPEC detect lamination?

Lamination is not affecting the reading.

Do weather conditions affect the BonPEC system performance?

The ambient electromagnetic field could be affected during severe storms, and therefore affect the generated magnetic field and the measurement.

Although the system is well sealed it is electronic equipment and in severe weather, shelter may be required for the computer and transmitter/receiver, with further sealing requirements of the sensors even to the point of requiring BonPEC subsea probes.

Does vibration / harmonics from rotating equipment have an effect on BonPEC?

Yes, all moving ferritic objects within the generated magnetic field will affect the reading. Their influence depends on the received signal strength. How stronger the received signal how weaker is the influence of vibration.

What effect does the insulation and cladding have on the BonPEC data/readings?

Insulation and cladding increase the lift off and hence the footprint. Cladding with magnetic properties enlarges the integration or magnetic footprint area.